flour grain bin

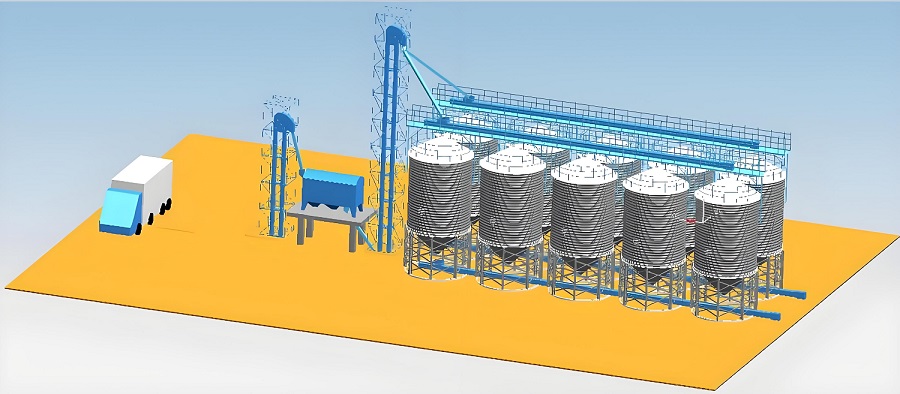

A flour grain bin is a specialized storage facility designed for the safekeeping of flour. These bins are typically engineered to protect flour from moisture

flour grain bin Introduction

A flour grain bin is a specialized storage facility designed for the safekeeping of flour. These bins are typically engineered to protect flour from moisture, pests, contamination, and other factors that may lead to a decline in the quality of the flour. The design and construction of a flour grain bin take into account various factors to ensure the quality and safety of the flour during storage.

Characteristics of Flour grain bin

Sealing

Flour grain bins usually have good sealing capabilities to prevent external air and moisture from entering, which helps to prevent the flour from becoming damp and moldy.

Temperature and Humidity Control

The interior of the grain bin is often equipped with a temperature and humidity control system to maintain suitable levels of temperature and humidity, as both excessively high and low humidity can adversely affect the quality of the flour.

Pest and Rodent-proof Design

The design of the flour grain bin considers measures to prevent pests and rodents from entering, as they can consume the flour or contaminate the storage environment.

Ventilation System

To maintain the freshness of the flour and prevent mold, the grain bin is fitted with an effective ventilation system to ensure air circulation and heat dissipation.

Fire Safety

Since flour is combustible, flour grain bin need to have good fire prevention design and facilities, such as installing automatic sprinkler systems and smoke detectors.

Loading and Unloading System

To facilitate the entry and exit of flour, grain bin are equipped with specialized loading and unloading systems, such as conveyor belts and elevators, to improve efficiency and reduce manual operations.

Quality Monitoring

Modern flour grain bin may be equipped with advanced monitoring systems for real-time surveillance of key parameters such as the temperature, humidity, and quality of the flour, ensuring the timely detection and handling of potential issues.

The design and operation of flour grain bin are crucial for ensuring the safe storage and supply of flour, especially in large-scale flour production and processing enterprises. Through effective storage management, flour grain bins help maintain the quality of flour, extend its shelf life, and thus provide consumers with fresh and safe food products.

Structure of flour grain bin

Main Structure

The main structure of a grain bin is usually made of concrete or steel to ensure sufficient stability and load-bearing capacity.

Bin Walls

The bin walls constitute the exterior part of the grain bin, typically made of concrete, steel plates, or other durable materials to protect the grain from external influences and provide structural support.

Bin Roof

Located at the top of the grain bin, the bin roof is typically made of steel plates, concrete, or other durable materials to cover and protect the grain from weather and other external factors.

Bin Floor

The bin floor is the bottom structure of the grain bin, usually made of concrete or reinforced concrete to support the grain stored inside the bin and provide structural stability.

Unloading Equipment

Grain bins are typically equipped with unloading equipment to unload the grain from the bin to transportation vehicles or other storage facilities. This equipment may include conveyors, unload hoppers, etc.

Ventilation System

To maintain the quality of the grain, grain bins are usually equipped with ventilation systems to ensure air circulation and humidity control, preventing grain from becoming damp or moldy.

Temperature Control Equipment

Some large grain bins may also be equipped with temperature control equipment to ensure that the storage temperature of the grain remains within the appropriate range, thereby extending the shelf life of the grain.

Safety Equipment

To prevent fires, explosions, or other safety issues, grain bins are typically equipped with corresponding safety equipment such as fire alarm systems, fire suppression equipment, etc.

Advantages of Flour grain bin

Strong Preservation

Grain bins for flour storage adopt sealed storage, effectively preventing air, moisture, pests, and other external factors from affecting the grain, thereby extending its shelf life.

High Space Utilization

Due to the vertical stacking capability of grain bins, they can utilize storage space more efficiently, saving area and accommodating various scales and shapes of grain storage needs.

Flexibility

Grain bins can be flexibly configured and designed to meet different types, scales, and shapes of grain storage, catering to users’ personalized requirements.

Convenient Management

Equipped with modern automated control systems, grain bins enable automated management, monitoring, and control of grain, improving storage efficiency and reducing management costs.

High Safety

Grain bins feature sturdy structural designs and safety facilities, effectively preventing safety risks such as fire, explosion, and theft, ensuring the safe storage of grain.

Environmentally Friendly and Energy Efficient

Grain bins incorporate environmentally friendly and energy-efficient technologies and equipment in their construction and operation, reducing environmental impact and energy consumption in line with sustainable development principles.

Economical

Grain bins have relatively low investment costs, and due to their long-term preservation effect and efficient management methods, they yield high economic benefits and investment returns.

Application scope of flour grain bin

Coban Silo is widely used for grain storage such as wheat, corn, soybean, paddy, rice, soybean meal, barley, malt, sunflower seeds, rapeseed, peanuts, flour, and other powder materials, oat, special Silo, and seeds, etc.

flour grain bin technical parameters

Scientifically speaking, the Silo capacity should be measured with volume (m3). Even in the same grain Silo, the storage tons will be different for different grains with different densities. The following table is calculated based on a Silo density of 0.75kg/m3, and surely HKB customizes Silo systems unique for you.

| Most Popular Hopper Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 50Ton | 100Ton | 150Ton | 200Ton | 300Ton | 500Ton | 1000Ton | 1500Ton |

| Model | TCZK

03605 |

TCZK

04507 |

TCZK

05507 |

TCZK

06406 |

TCZK

07307 |

TCZK

07313 |

TCZK

11010 |

TCZK

12811 |

| Diameter(m) | 3.667 | 4.584 | 5.500 | 6.417 | 7.334 | 7.334 | 11.000 | 12.834 |

| Total Height(m) | 9.56 | 12.53 | 13.25 | 12.85 | 14.70 | 21.42 | 20.95 | 23.51 |

| Volume(m³)

Density:0.75ton/m³ |

69 | 150 | 222 | 273 | 415 | 699 | 1346 | 2039 |

| Most Popular Flat Bottom Steel Silo Technical Specifications | ||||||||

| Capacity | 1000Ton | 1500Ton | 2000Ton | 2500Ton | 3000Ton | 5000Ton | 8000Ton | 10000Ton |

| Model | TCK

10014 |

TCK

11915 |

TCK

13715 |

TCK

15514 |

TCK

15518 |

TCK

18321 |

TCK

24718 |

TCK

25621 |

| Diameter(m) | 10.084 | 11.918 | 13.750 | 15.584 | 15.584 | 18.334 | 24.751 | 25.668 |

| Total Height(m) | 18.69 | 20.34 | 20.87 | 20.30 | 24.78 | 28.60 | 26.99 | 30.60 |

| Volume(m³)

Density: 0.75ton/m³ |

1335 | 2009 | 2701 | 2467 | 4145 | 6693 | 10879 | 13484 |

After-sale Service

- – HKB provides advanced grain safety storage technology to assure your grain silo 100% quality stability.

- – grain silo Quality guarantee is one year after installation and commissioning or 18 months after leaving China Port. Maturity is the first.

- – 7 days x 24 hours service, within 24 hours reply/solve of any technical issues upon request.

- – Routinely telephone track to remove all might be problems grain silo or issues guarantying the whole system grain silo long-lasting safety and reliability.

- – HKB will consider all other needs like customs clearance, sea delivery, insurance, customs tax benefit plan, documentation, etc. So our respected Users feel so relaxed and easy to get the grain silo system well.